FAQs

Apparel & Fabric Printing

Printing Options

From long life crisp single colour or vibrant quality full colour, we are able to print from logos and messages to images and just about anything. We print on most fabrics especially Cotton, Polyester and most Nylons. we print on most aapparel items from Tops and Hoodies to Caps and Aprons and Lanyards. Craft items from Quilting fabrics, bags, Pillow slips to Table covers can all be printed.

- HTV Colour Ultra printing: Heavy Duty Matt Polyurethane Revolution vinyl which is ultrathin, stretchable and soft. Long life + colour fast 200 + wash

- Full Colour Ultra Printing: Bulk Commercial Ultra colour printin. Heavy Duty and thin to move with the wearer. Long life + colour fast 150 + wash

- Full Colour Heavy Duty Printing: Heavy duty colour printing with the micromask option for longer life and finer details. Heavy Duty and the thinnest of full colour printed films. Long life + colour fast 40 + wash

Our Washing - Care Instructions for apparel printed here at allBIZ is

- Turn Garment inside out

- Use mild detergent

- No Bleach

- No Soak

Fun tansfers 5+ Wash life

- Max 30°C wash

- No Tumble Dry

- No Dry Cleaning

- Iron Reverse side on low heat

Heavy Duty Full Colour 40+ Wash life

- Max 40°C wash

- No Tumble Dry

- No Dry Cleaning

- Iron Reverse side on low heat

ULTRA Full Colour 150 + Wash life

- Max 40°C wash

- No Tumble Dry

- No Dry Cleaning

- Iron Reverse side on low heat

ULTRA HTV Colour 200 + Wash life

- Max 60°C wash

- No Tumble Dry

- No Dry Cleaning

- Iron Reverse side on low heat

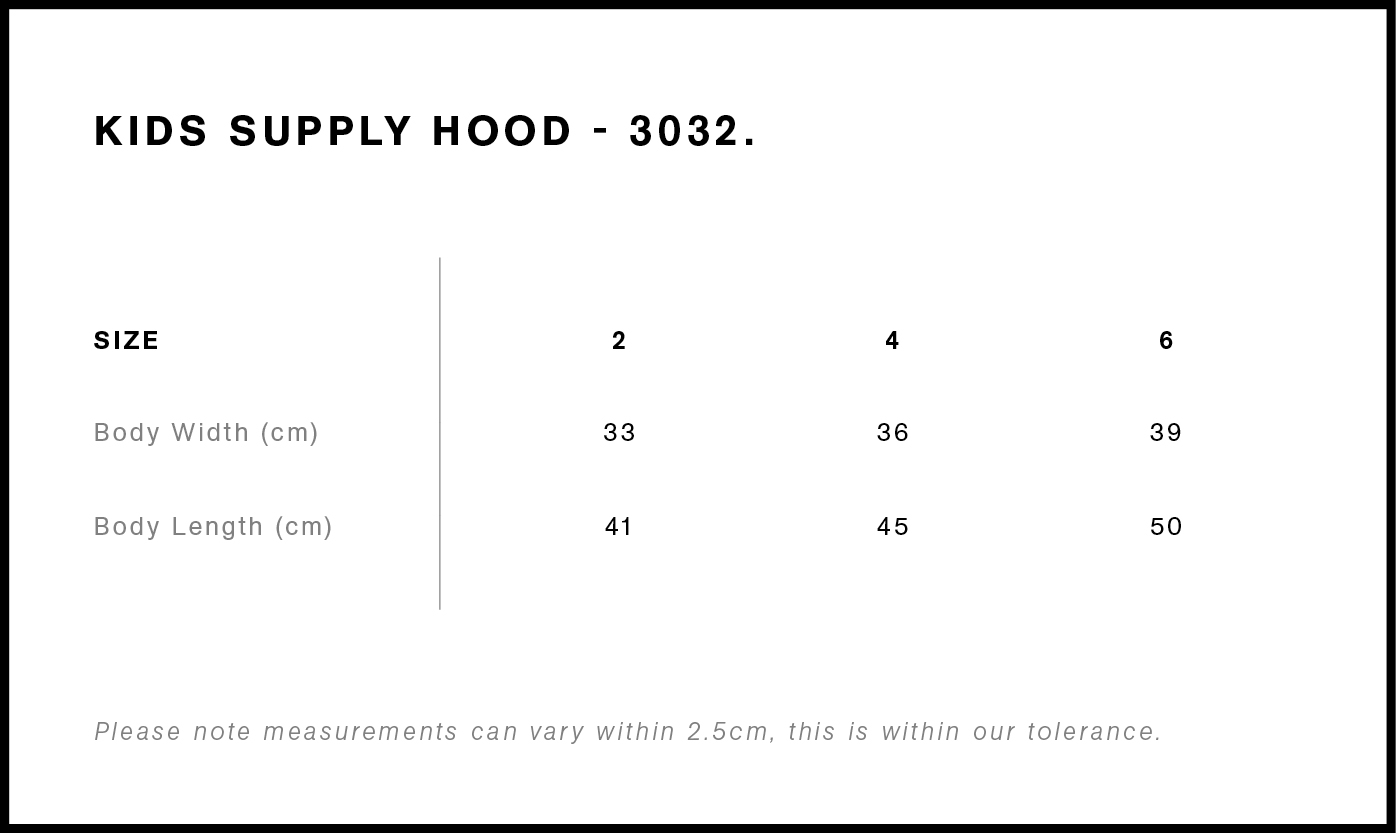

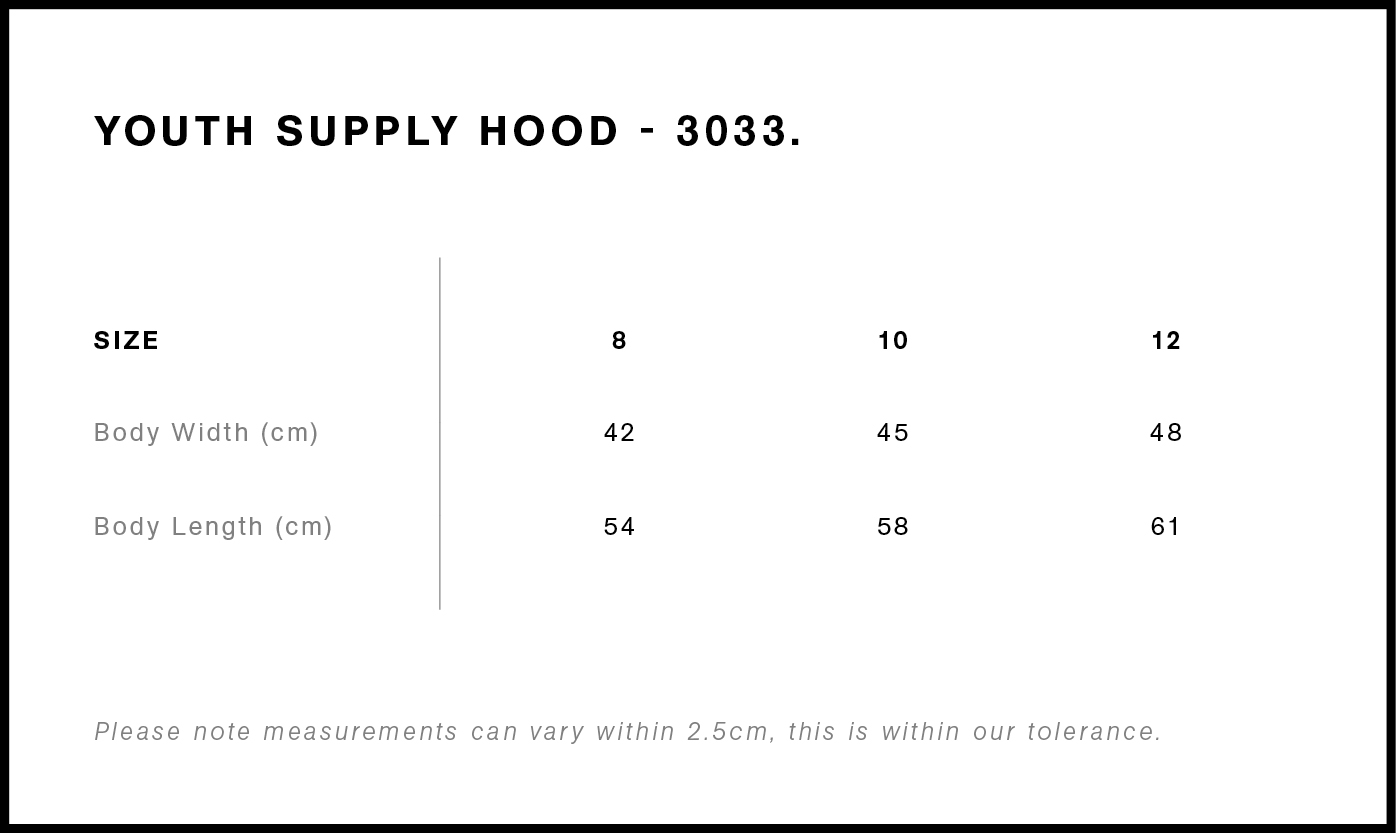

For sizing information please visit - FAQ's

AS Brand

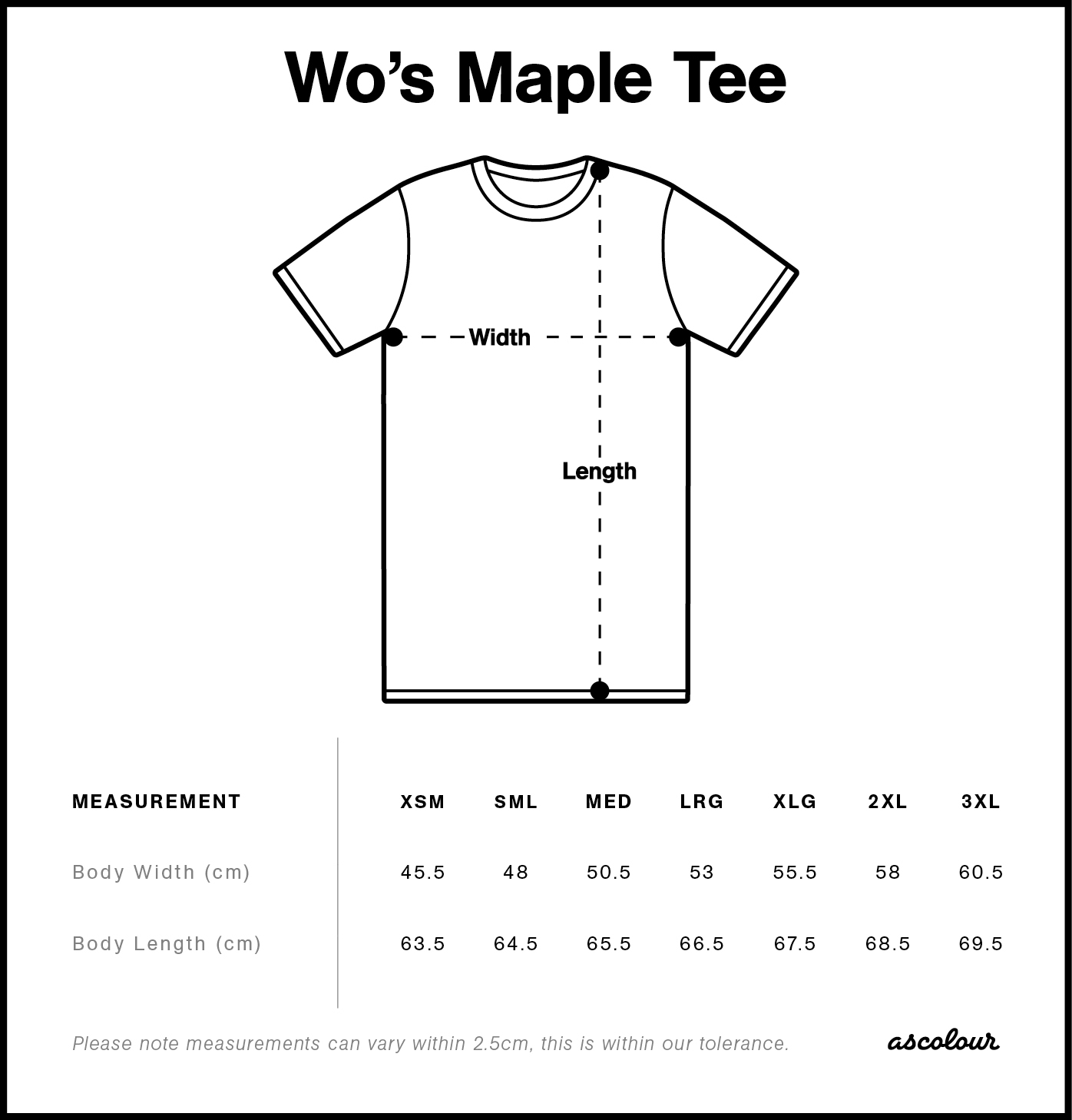

Maple WOs Tee (Code: 4001)

Fit: Regular

Fabric: Mid weight, 180 GSM, 28-singles, 100% combed cotton (marles 15% viscose)

Construction: Neck ribbing, side seamed, shoulder to shoulder tape, double needle hems, preshrunk to minimize shrinkage.

Size: Extra Small to 3XL.

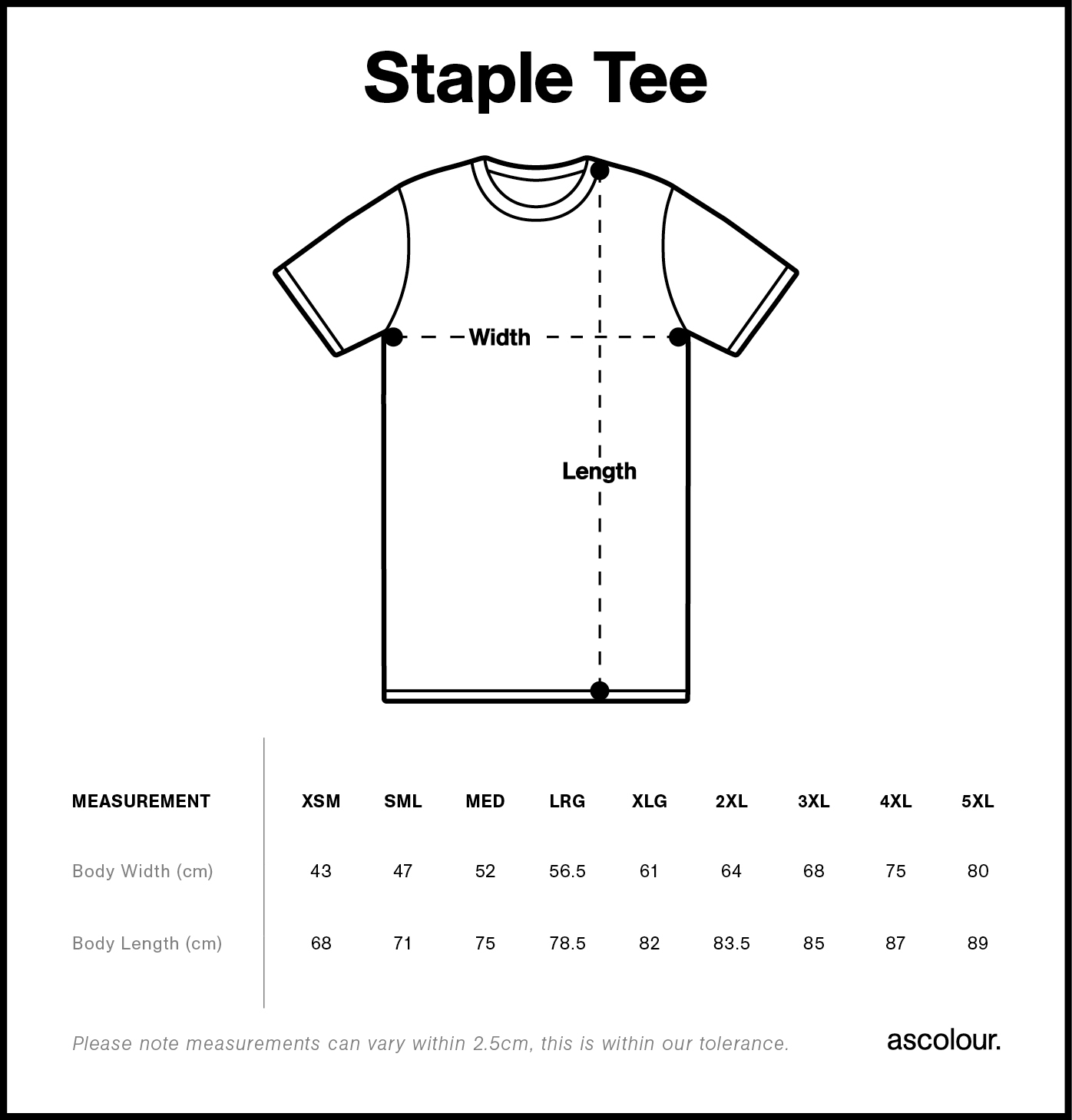

Staple Mens Tee (Code: 5001)

Fit: Regular

Fabric: Mid weight, 180 GSM, 28-singles, 100% combed cotton (marles 15% viscose)

Construction: Neck ribbing, side seamed, shoulder to shoulder tape, double needle hems, preshrunk to minimize shrinkage.

Size: Extra Small to 5XL. Note 4XL & 5XL only available in select colours

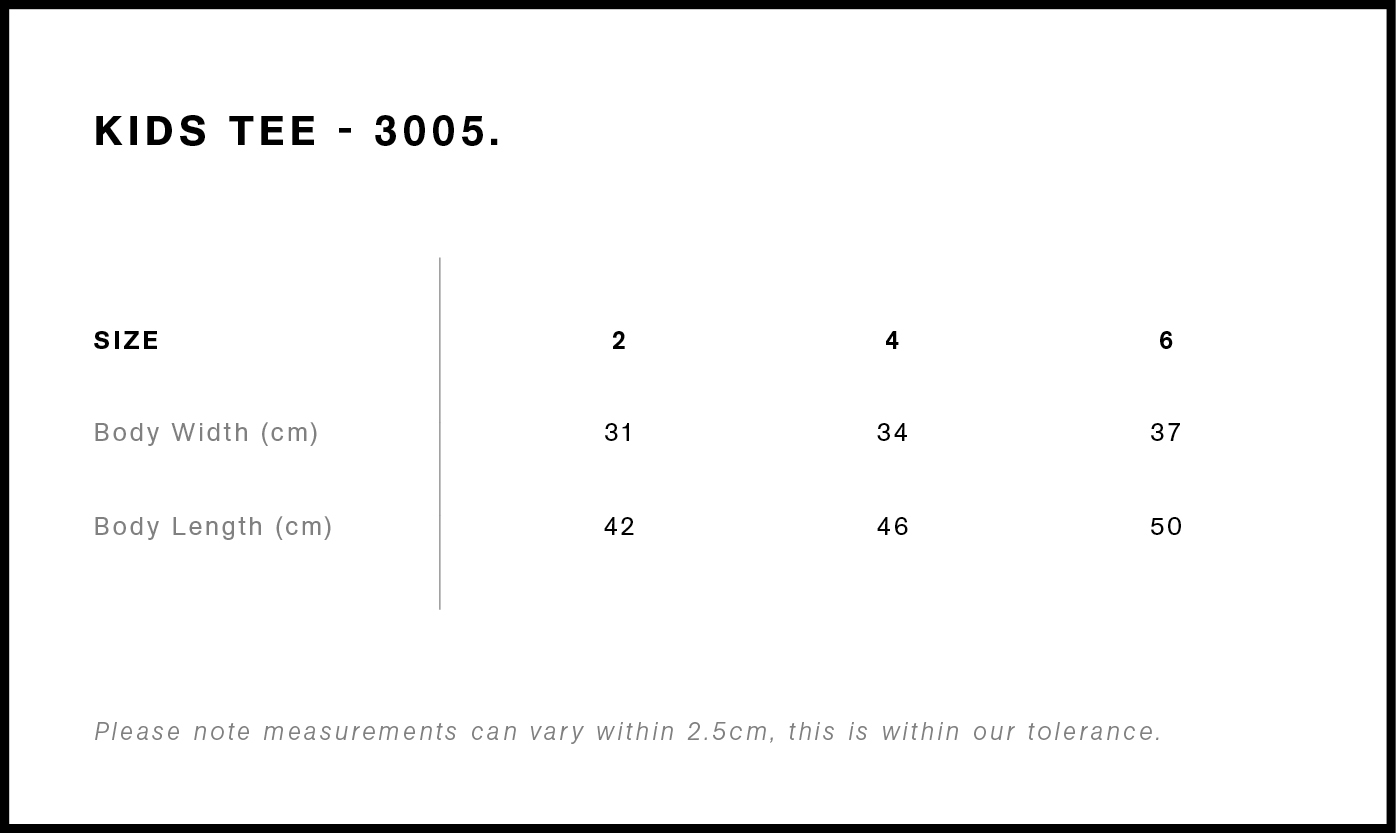

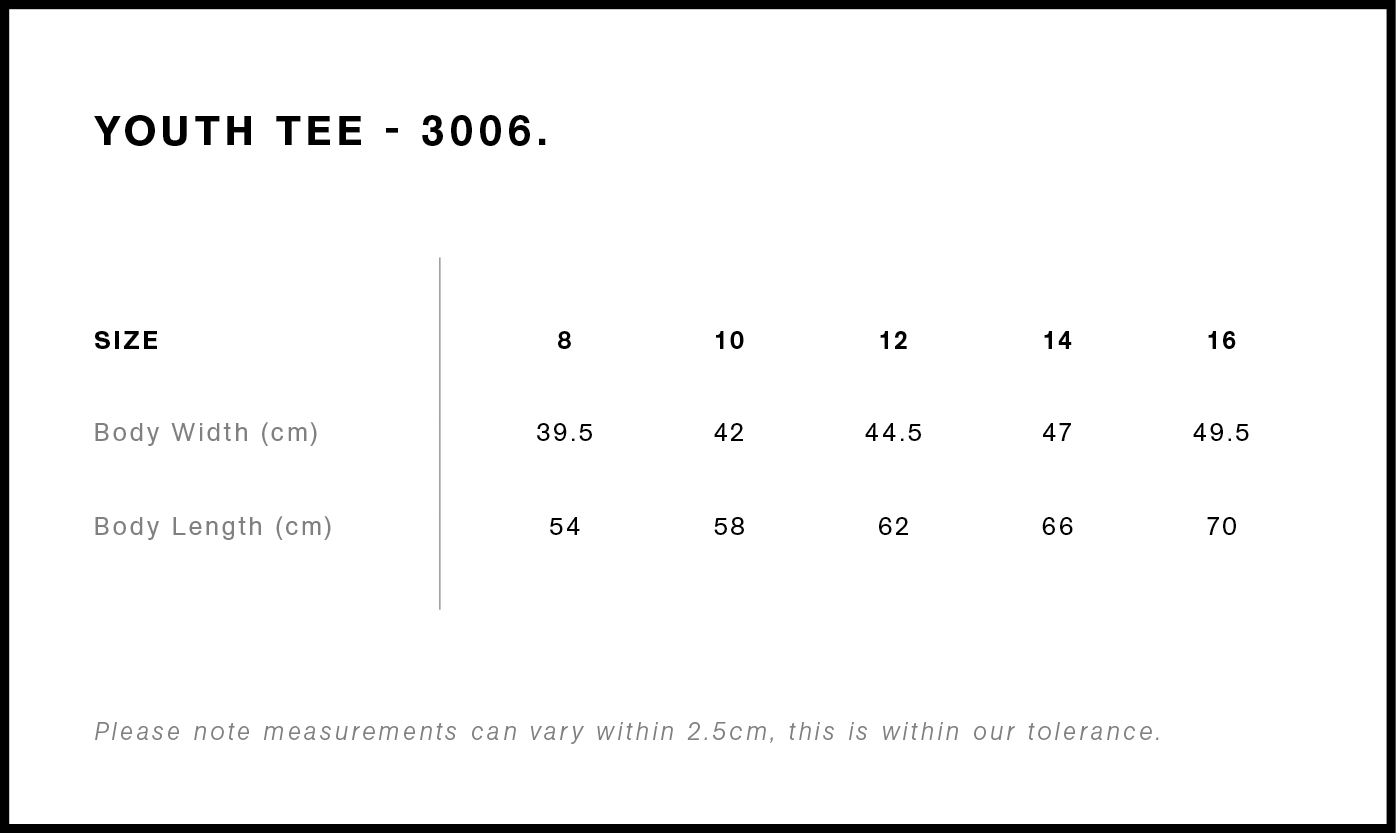

Youth Staple Tee (Code:3006)

Fit: Regular

Fabric: Mid weight, 180 GSM, 28-singles, 100% combed cotton (marles 15% viscose)

Construction: Neck ribbing, side seamed, shoulder to shoulder tape, double needle hems, preshrunk to minimize shrinkage.

Size: 8 to 16

Chad Polo-Shirt Adult (Code: 5402)

Fit: Slim-regular

Fabric: Heavy weight, 220 GSM, 20-singles, 100% combed cotton (marles 15% viscose)

Construction: Short sleeve collared polo shirt, 3 button placket, tonal buttons, split detail at sides, side seamed, double needle hems, preshrunk to minimize shrinkage.

Size: Extra Small to 5XL. Note 4XL & 5XL only available in select colours.

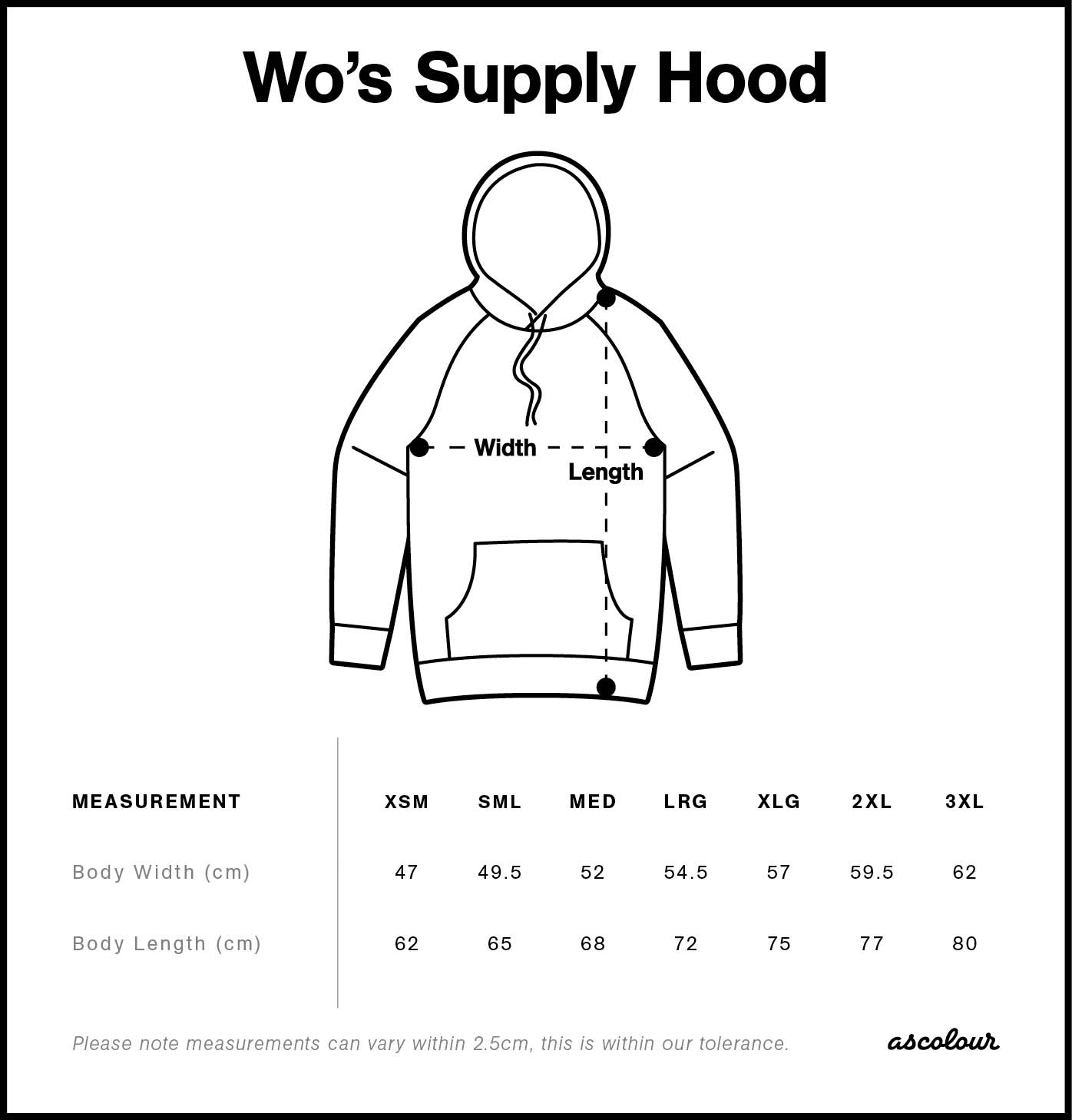

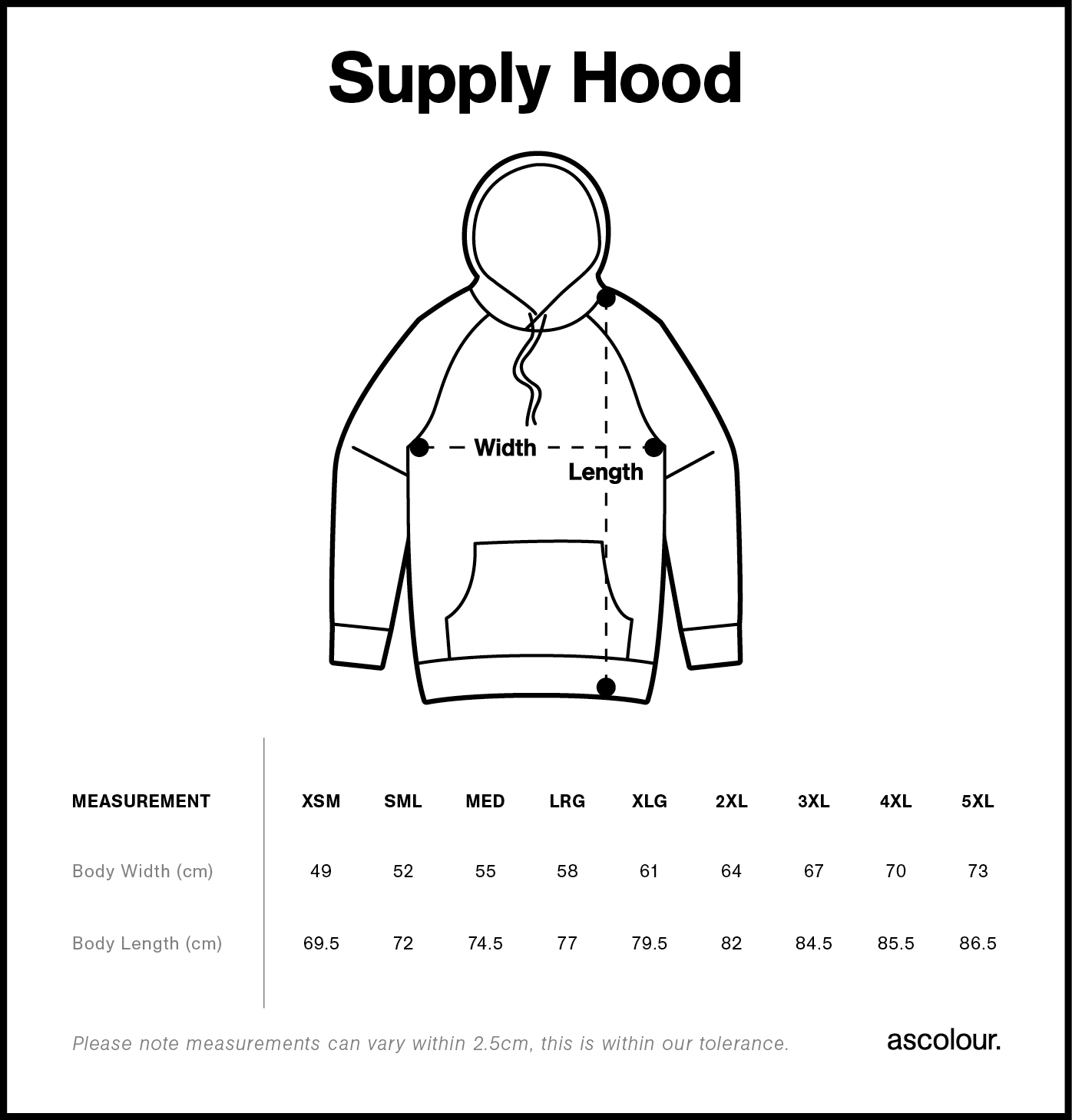

Supply WOs Adult Hoodie (Code:4101)

Fit: Regular

Fabric: Mid weight, 290 GSM, 80% cotton 20% polyester anti-pill CVC fleece.

Construction: Pullover hood, raglan sleeves, kangaroo pocket, lined hood, tonal drawcord, sleeve cuff ribbing, preshrunk to minimize shrinkage.

Size: Extra Small to 2XL.

Supply Mens Adult Hoodie (Code:5101)

Fit: Regular

Fabric: Mid weight, 290 GSM, 80% cotton 20% polyester anti-pill CVC fleece.

Construction: Pullover hood, raglan sleeves, kangaroo pocket, lined hood, tonal drawcord, sleeve cuff ribbing, preshrunk to minimize shrinkage

Size: Extra Small to 5XL. Note 4XL & 5XL only available in select colours.

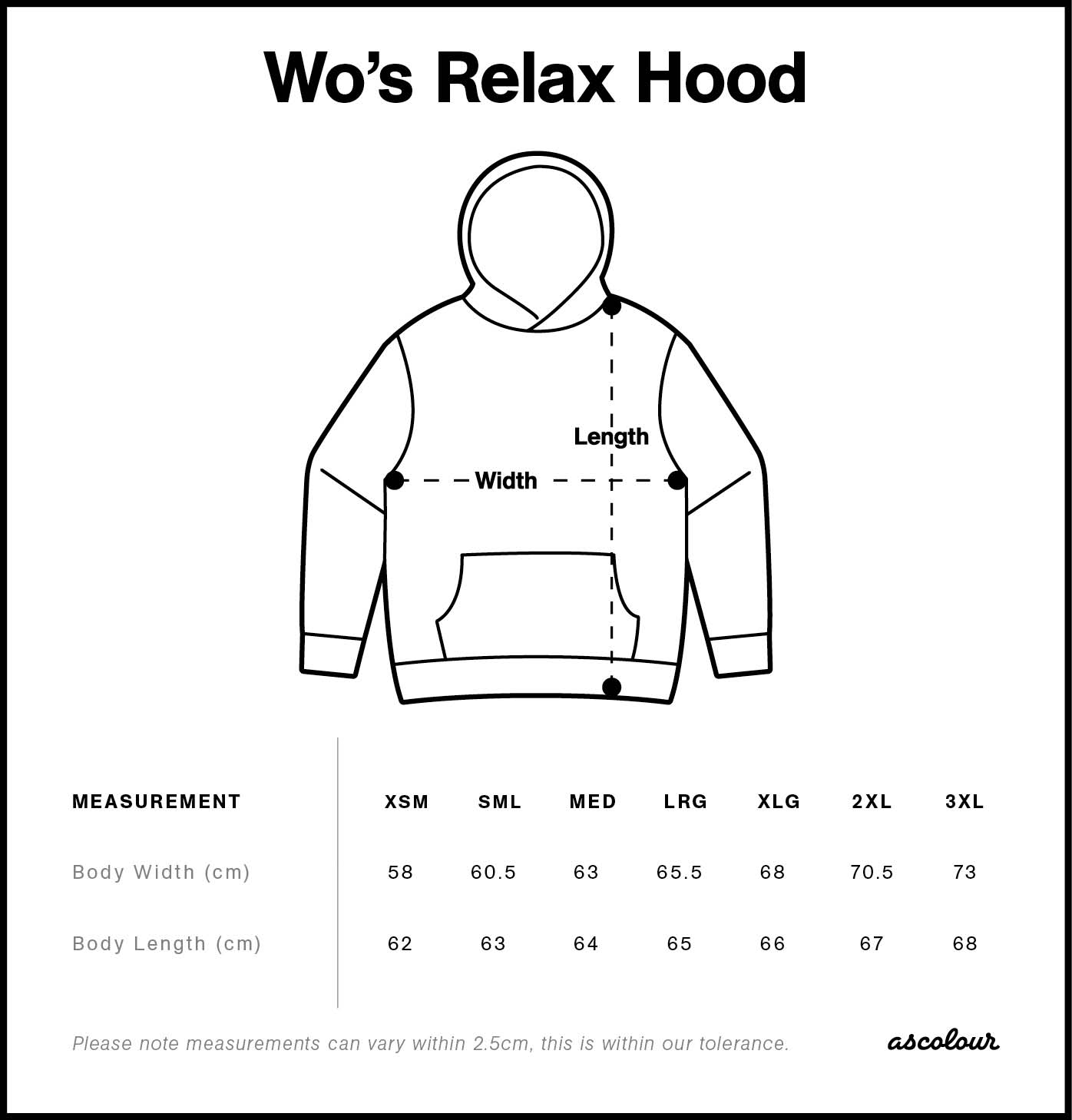

Relax WOs Adult Hoodie (Code:4161)

Fit: Relaxed

Fabric: Mid weight, 320 GSM, 80% cotton 20% recycled polyester CVC fleece.

Construction: Pre-shrunk to minimize shrinkage, pullover hood, drop shoulder, kangaroo pocket, self-fabric lined hood, no drawcord, sleeve cuff ribbing.

Size: Extra Small to 2XL.

BH Wear Brand

Basic Cotton Tees - BH

Fit: Classic Fit with a taped neck and shoulders

Cotton: 180 GSM 100% cotton with a smooth & soft hand feel.

Finish: Double needle sleeve and bottom hems and a seamless double needle 2.2cm collar. Pre-shrunk to minimize shrinkage

Size: Small - 3XL. Half Chest Length: -

S 46cm 71cm : M 51cm 74cm : L 56cm 76cm : XL 61cm 79cm : 2XL 66cm 81cm : 3XL 71cm 84cm

Adult Sports Polo Shirt - BH

Fabric: 150gsm 100% Polyester moisture wicking fabric designed to keep you cool and dry

-New generation BHCOOL mesh feels great against the skin

-Easy care fabric, quick drying

Finish: Raglan shaped sleeve and flat locked seams

Size: Small to 5XL

Saftey Wear

W1 Safety Vest Brand: BH

120gsm 100% Polyester for durability

Complies with Standards AS/NZS 1906.4:2010 and AS/NZS 4602.1:2011 Day Only

Front garment with velcro closure and Grey binding

Sizes: Small - 7XL

W2 Classic Polo - BH

Brand BH Wear. Classic fit.

100% Polyester and 170gsm fabric

Conforms to AS/NZS 4399:1996 for UPF Excellence Protection(UPF 40-50)

Conforms to AS/NZS 1906.4:2010 and AS/NZS 4602.1:2011 Class D, day use only

Moisture wicking and quick drying fabric

Sizes: Small - 7XL

W8 Breezy Hi-Vis Shirts - BH

100% cotton in a 150gsm pre-shrunk drill

Complies with AS/NZS 4399:2017 for UPF protection (UPF 50+)

Complies with standard AS/NZS 1906.4:2010 and As/NZS 4602.1:2011 Day Only

Enhanced performance through mesh side panels and back

Two front pockets with pen insert

Contrast panel on front, back, and collar

Double stitch reinforecement

Sizes: Small - 5XL

All ORDERS will be collected from the Carnival on the Day

- Stricktly No refunds or exchanges for custom printed items

- Hoodies and T Shirt supply is stricktly While Stocks Lasts:

Printing including

- Printed Design Front & Back with a Club list on the back

- Your Name or Nickname Printed on the back if ordered and paid for

- All Names will be printed in upper Case in FONT used

- All Names will be printed in the Design colour indicated

- The size of the Font used for your Name / nickname will be adjusted to fit the width of the print area. (long names will print in a smaller Font size)

Colours seen on screen are RGB while printing is CMYK so the finished printing may look different from screen colours.

While every effort is made to maintain consistant garment colours, colour variations from top to top or Batch to Batch is beyond our control

In the case of a Godzilla attack tops will be delivered to SUNA for collection as soon as possible after the Carnival. (Godzilla Attacks rarely happen)

We can print on most garment from basic T Shirts, Safety Vests and Tops, Hoodies, Polos and Caps. Cotton blens, Polyester and most Nylons give great results.

MUST BE CLEAN: for printing and pressing the surface must be free of dirt, grease, oil, chemicals and any barriers to good adhesion.

SMOOTHER or polished fabrics are prefered: HTV and full colour transfers will not stick to rough or uneven surfaces.

HTV and Full colour transfer material will not stick to fabrics containing Anti-bacterial treatments.

For best results Garments should be washed before printing

Please NOTE:Printing on supplied stock is at your own risk. We try to apprase all garment before we print but there are often things beyond our control (variations such as stock, finishes, rogue threads, dyes and preserving chemicals are just a few). that can affect the finish of our work.

Single Colour Designs - HTV Heat Trasfer Vinyl

HTV – Heat Transfer Vinyl is best for lettering, numbers or single colour shapes and designs

- Heat Transfer Vinyl is a long-life vinyl that is transferred by heat & pressure onto fabrics. Professional results are achieved using quality vinyl, cut using a cutting machine and transferred to fabric using a heat press.

- HTV designs are cut to the actual outline of the design. Any excess vinyl is “weeded” – removed from the design delivering a clean – no background finish.

- SVG or cut files are required to create a HTV design

- HTV designs are clean, crisp, durable, and long-life

Full Colour Designs

Full Colour Ultra Printing is best for photos, pictures or images that have multiple colours, gradients, effects, or drop-shadows.

- Printing is a printed long-life film that is transferred by heat & pressure onto fabrics. Professional results are achieved using quality film and commercial printers, transferred to fabric using a heat press.

- Full Colour Ultra printed designs are electronically weeded. With the correct file formats backgrounds are removed from the design delivering a clean – no background finish.

- SVG, Pdf, Vector or PNG files are required to create a no background design. (backgrounds must be supplied as transparent)

Competition Conditions of Entry

Competition Conditions:

The duration of each competition will be advised on our socials, emails and in-store

Judge’s decision is final

- Where a "Create" something is a condition of entry: The allBIZ Graphic team & Management will judge the winning entry.

- Where a “Share to win” or “Like us on” is a condition of entry: The allBIZ Graphic team & Management will use a random numbering system to choose the winner

- Where a “Purchse to Enter” is a condition of entry: The allBIZ Graphic team & Management will use a random numbering system to choose the winner

- All winners will be advised privately and winners’ info will remain anonymous unless advised otherwise. All winning entries will only be shared on socials & in-store when permission is given by the winner.

- allBIZ Staff are not allowed to enter design-based competitions

Art Information

Files larger than 5mb may not leave your email server, and if they do, they may not make it to ours.

Use www.wetransfer.com to send files larger than 5mb. It is a free service and allows up to 2Gb of data transferred at one time. Just put in your email address, and ours ( print@allbizsupplies.biz ) and upload your files. We will receive a notice that we have files waiting. You will receive a notice when we download.

Note that if you have very large files it will take some time to upload.

Maybe. It depends on the original. Often the original format won't have the detail and info we need. It is physically possible to change file formats, but it may not help or be useable.

Labels

Label Stock

Paper Gloss Strong Self Adhesive Permanent Labels

Permanent gloss coated paper with super strong adhesion.

Long lasting permanent super strong adhesive labels for all uses including glass, plastic, metal and paper surfaces. This permanent label becomes water resistant once printed.

This super strong adhesive gloss coated label stock printed in high resolution on our digital presses offer excellent colour and durability. Gloss permanent label stock is an ideal choice for internal applications, glass, metal & product stickers.

Rated: Durability medium – long term internal

Conformability: good

Stability: very good

Adhesion: very strong

Vinyl Monomeric Self Adhesive Durable

This high quality film is suitable for short-term external applications and long-term internal uses.

Vinyl monomeric vinyl offers high resolution printing with excellent colour & durability

Economical 2 year monomeric vinyl partnered with our UV solvent inks and high resolution printing offer excellent colour and outdoor durability. With up to 2 years exterior life our Monomeric vinyl is an ideal choice for short term external use, internal applications, and glass, metal & product stickers

Rated: Durability long term internal and 2 year maximum outdoor lifespan

Conformability: very good

Stability: very good

Adhesion: very strong

Available in: White Gloss or Matt finish and Clear gloss

Add a laminate finish to protect the print from scuffing & increase the longevity of your labels

Vinyl Polymeric Self Adhesive Heavy Duty

This high quality film is suitable for medium- long term external applications and longer-term internal applications.

Vinyl Polymeric offers high resolution printing with excellent colour & durability

Heavy duty 5 year external high performance polymeric vinyl partnered with our UV solvent inks and high resolution printing offer excellent colour and outdoor durability and is less prone to shrinkage. A popular choice for exterior applications on flat or slightly curved surfaces, long life internal uses, heavy duty product labels, metal, glass and plastic applications.

Rated: Durability long term internal and 5 year maximum outdoor lifespan

Conformability: excellent

Stability: excellent

Adhesion: very strong

Available in: White Gloss or Matt finish and Clear gloss

Add a laminate finish to protect the print from scuffing & increase the longevity of your labels

Synthetic Polylazer Clear Self Adhesive

This waterproof crystal clear label is suitable for short-term external applications and long-term internal use. Polyclear offers high resolution printing with excellent colour & durability. We suggest smudge testing for cosmetic & chemical product use.

Economical 2 year + polyclear partnered with our high resolution digital printing offer excellent colour and heat & water resistant properties. With up to 2 years exterior life our polyclear is an ideal choice for short term external use, internal applications, and glass, metal & product stickers.

Rated: Durability long term internal and 2 year maximum outdoor lifespan

Conformability: good: (we suggest smudge testing for cosmetic & chemical product use)

Stability: good

Adhesion: strong

Laminate finish not available

allBIZ Label Stock Uses

Paper Gloss

Paper Gloss Strong Self Adhesive Permanent labels & stickers. coated

This stock is an ideal choice for internal applications including

Glass and plastic: jars, bottles, wine bottles, food jams & condiments, party & gift bags

Skincare, body care, cosmetics & beauty products.

Candles, toys, gifts, Bonbonniere, wood, metal & product stickers.

This permanent label becomes water resistant once printed.

Vinyl Monomeric Self Adhesive – extremely Durable

This high quality film is water and fade proof suitable for short-term external applications and long-term internal uses. Available in gloss white & clear stock.

This is an ideal choice for labelling jars, bottles, skin & body products where shower or water proof is a necessity

Glass and plastic: jars, bottles, wine bottles, food jams & condiments.

Skin care, body care, cosmetics & beauty products.

Candles, Toys, gifts, Bonbonniere, wood, metal & product stickers.

All trade, industrial and commercial uses.

This permanent label is long lasting and waterproof

Vinyl Polymeric Self Adhesive Heavy Duty

This high quality film is water and fade proof with a long external life suitable for long-term external internal applications. Available in white & clear stock.

All trade, industrial and commercial uses including, electrical, plumbing, general sign age and display

Corflute, A frames, windows and general signage.

Bikes, boats, vehicles, trailers and building signs

Glass and plastic, candles, bumper stickers, wood, metal & commercial product stickers.

This permanent label is long lasting UV and waterproof

Add a laminated finish to prevent scuffing.

Tests should always be conducted to ensure the label type suits the entire end use application criteria. By ordering a proof a sample of label material can be supplied for testing.

Vinyl life is affected by environment, temperature, humidity, wear, and the surface condition at installation.

For the best results:

SURFACE MUST BE CLEAN: for installation the surface must be free of dirt, grease, oil, chemicals and any barriers to good adhesion.

SURFACE MUST BE SMOOTH: vinyl will not stick to rough or uneven surfaces.

PAINT MATTERS: Vinyl can be applied to either enamel or latex painted walls, but the best surface for adhesion is semi-gloss enamel. Latex mat and semi-mat are more porous, and over time matting agents may migrate to the surface and interfere with adhesion.

Vinyl will not stick to paint containing Teflon or silicone (washable and stain-free), or VOC-free (Volatile Organic Compound) “green” paints.

Paint must be fully cured before vinyl installation.

It is best to let paint dry one to two months before vinyl application, otherwise the paint curing will interfere with the vinyl adhesive.

CLEANING: wipe your vinyl with a chemical-free damp cloth.

Permanent adhesive: is designed not to be removed. This adhesive will stick for the life of its intended use. We recommend applying pressure with the application of our permanent adhesive labels. Maximum adhesion is achieved within 48 hours

Repositionable Adhesive: offer short term (24 hours) repositionability. This adhesive is great for refrigerated or damp conditions. Repositionable labels can become permanent over time

Removable adhesive: is designed to allow removability long term.

Printing Hints

Our skilled graphic designers specialise in refreshing and fixing your files and logos making them print-ready for products of all types and sizes. We can check you file, identify any inadvertent errors and offer solutions including recreating or fixing your files. Prices start from $16.50

SPECIAL PDF Files: Fillable Forms and Editable Files

PDF fillable forms are forms that can be filled in onscreen by keyboard and mouse clicks. Editable PDF files are similar, but instead of looking like a form, they allow blocks of text to be edited by a PDF reader, or sometimes, online with a web browser.

Both PDF types are very useful, but often make very bad masters for professional print. Both types of changeable PDF can completely drop the editable information when printed, or print out odd characters instead of text.

Make sure your print files are NOT forms or editable files. If you have a PDF writer, open the editable file and choose “print,” which actually makes a PDF. The resulting PDF may (or may not...) drop all of the editable features.

If you can’t get rid of the editable features, send us the file. We have professional software that can help pull out the edit features (starts at $16.50).

Slight irregularities occur normally in the surfaces of linen, textured and natural stocks which affects the evenness of the printing process. This should not be regarded as defects in the stock or print finish.

We sure do!

1 - Product Help Guides

Our guides have all the info you need if you are familiar with graphic art. Go to the product you are interested in and click the ARTWORK TEMPLATE tab.

2 – FAQ

Many common questions are answered in the FAQ, such as bleed, trim, resolution, etc.

Jobs need:

- to be in PDF format (PDF/X-1a is better)

- FONTS embedded (or converted to Curves/Paths/Outlines )

- IMAGES 600 to 300ppi (less resolution and they will print fuzzy and blocky)

- CMYK colour only (do not use RGB or Spot colour or mix them)

- FLATTEN transparencies/layers (or you will get odd stripes/blocks)

- BLEED - 3mm, and 3mm Safe Area away from edge

- TRIM MARKS and TRIM BOX (bleed jobs) - set to final cut size (or your job will be cut wrong)

3 – Online Design Studio

Our easy to use studio lets you be as creative as you want. You have a choice of fonts, lines and shapes, colours, and images (a selection from our own online library and your own images).

4 - Templates

Many of our products have a wide range of pre-made templates to choose from. Customise with your own information (and even change colour, fonts, and move elements about).

5 – The allBIZ Graphic Team

If art and pre-press are a mystery, we can either make your files print ready, or create from scratch. Prices start at $16.50.

Add a minimum of 3mm bleed ( extra image ) on all sides of your design. This will be trimmed off after your page has been printed. This ensures your document will show no white lines or borders on your page.

A screen image is made of light and will look bright and sharp. A printed image is made from ink/toner, so it is darker.

MORE INFORMATION

Screen images are made from tiny squares or sometimes rectangles, called pixels(“picture elements”). Each pixel can be almost any colour and any intensity, making a screen image seem to have great detail and shading. Screen resolution is properly called PPI, for Pixels Per Inch. Printed images are made from dots of toner or ink. Each dot can only be either Cyan,Magenta, Yellow, or Black. There is no other colour choice, and there is only one intensity. Where a screen can display a light grey pixel (by mixing RGB colours), a printer can only plop down a black dot. To get grey, the printer has to put small dots of black with empty space between them, to give the illusion of grey. Print resolution is properly called DPI, for Dots Per Inch.

SHORT ANSWER

A computer monitor/TV screen doesn’t need much picture information to look sharp. The average resolution for a screen image is 96dpi (dots per inch). A printer works completely differently, and needs 300dpi to print crisp images.

MORE INFORMATION

Screen images are made from tiny squares or sometimes rectangles, called pixels(“picture elements”). Each pixel can be almost any colour and any intensity, making a screen image seem to have great detail and shading. Screen resolution is properly called PPI, for Pixels Per Inch. Printed images are made from dots of toner or ink. Each dot can only be either Cyan,Magenta, Yellow, or Black. There is no other colour choice, and there is only one intensity. Where a screen can display a light grey pixel (by mixing RGB colours), a printer can only plop down a black dot. To get grey, the printer has to put small dots of black with empty space between them, to give the illusion of grey. Print resolution is properly called DPI, for Dots Per Inch.

Enlarge an image to twice the size and it will be half as sharp (very blurry).Reduce and image to half the size, and it will be twice as sharp.

The image has been squeezed in one dimension (in this case width). When changing a picture size make sure it changes proportionally (height and width change together).

The camera may have defaulted to the lowest resolution or been set to fit as many photos as the memory can hold. This is handy for fitting heaps of images, but quality is sacrificed. Set the camera to a higher (or even the highest) resolution. Your file sizes will be much larger, but your photos will print sharper.

Book and Booklet Printing

Book Printing hints

Supply two PDF files: one for the entire body of the book, and one for the cover (even if we are altering the cover for production). If you are unable to supply a single body file, we can merge multiple files for an extra charge.

Important note: The print file you supply should be totally ready for printing, as is. All proof reading and corrections should be complete before submitting the file. We will produce a hard copy Print Proof, but the Print Proof is just to make sure there are no printing technical errors. Do not re-read it and look for typos and mistakes. If something glaring and major does stick out, we can make corrections and produce a new print proof, but this is very expensive and will affect the production schedule and your deadline.

Vinyl and Signs

Car Vinyl Aftercare

DO

Hand wash your vehicle regularly with a soft cloth and car wash soap (non abrasive)

Dry the vehicle with a soft cloth to avoid water spots, which can be damaging

Park under cover when possible

DO NOT

Use solvents

Wash with anything that can scratch (brushes, car washes with bristles, etc.)

Wash the vehicle in direct sunlight or extreme temperatures

Park under trees for long periods (sap and bird droppings) if possible

Car Vinyl Preparation

WASH your vehicle with detergent and water one day before installation. The vehicle must be free of grease, wax, silicone, and anything that will prevent good vinyl adhesion.

If any vinyl is going near the wheel wells, they must be cleaned too (grease and road dirt can migrate and affect edges).

Do not use an ammonia-based glass cleaner on windows (residue can affect adhesion).

Important Vinyl Information

In general, printed vinyl needs to cure before it can be used or put through finishing steps like mounting or laminating. Solvent based inks need to “out gas,” and the vinyl itself needs time to regain dimensional stability and hardness after going through the printing process.

If you don’t wait, the vinyl can weaken and last only a fraction of its normal life. If laminated too soon, the gas coming off the ink will be trapped. The gas can react with the laminate adhesive, and ruin the work.

The minimum professional standard cure time recommended by equipment and material manufacturers for solvent inks is 48 hours. Temperature, humidity, and vinyl stock affect cure time and can easily make it 48 to 72 hours.

No one using quality solvent inks can provide vinyl “same day.”

Vinyl life is affected by environment, temperature, humidity, wear, and the surface condition at installation.

For the best results:

SURFACE MUST BE CLEAN: for installation the surface must be free of dirt, grease, oil, chemicals

and any barriers to good adhesion.

SURFACE MUST BE SMOOTH: vinyl will not stick to rough or uneven surfaces.

PAINT MATTERS: Vinyl can be applied to either enamel or latex painted walls, but the best surface for adhesion is semi-gloss enamel. Latex mat and semi-mat are more porous, and over time matting agents may migrate to the surface and interfere with adhesion.

Vinyl will not stick to paint containing Teflon or silicone (washable and stain-free), or VOC-free (Volatile Organic Compound) “green” paints.

Paint must be fully cured before vinyl installation.

It is best to let paint dry one to two months before vinyl application, otherwise the paint curing will interfere with the vinyl adhesive.

CLEANING: wipe your vinyl with a chemical-free damp cloth.

Vehicle Suitability Pre-application Checklist:

We at allBIZ uses high quality vinyl and materials rated upto 7 years for Australia’s harsh conditions and guarantee our workmanship but the life of our vinyls are affected by the preparation and quality of the base we install onto.

Checklist:

-WASH your vehicle with detergent and water one day before installation.

-Do not install vinyl to new paint. We recommend waiting for 6 weeks between painting and vinyl application.

-The perfect base for installing vinyl graphics is Factory painted cars – new vehicles

-Poor surfaces, badly painted or badly prepared surface and old aged paintwork will adversely affect all vinyl application and signage longevity.

-Risks exist with finishes including resprayed vehicles, replaced parts of vehicles, badly painted and or poor condition paint work, badly repaired or uneven surfaces. ( paints breaks down over time affects the adhesive of your vinyl)

-Uneven surfaces including rust are not recommended as they will affect and reduce the adhesion of your vinyl

-Domestic, industrial or non-hardened paint will reduce the life expectancy of your vinyl

-Poor surface preparation or poor quality paint and finishes will drastically affect and reduce the life of your vinyl signage

-The installation process may include hand cutting, trimming and vinyl repositioning which may leave marks in soft and poor finishes

Sign vinyl is UV, made to last with permanent adhesives but in many situations it can be removed.

Successful removal of Vinyl depends on the quality of the surface it was applied to.

- Poor surfaces, badly painted or badly prepared surface and old aged paintwork may result in chipping or damaged to your paintwork when vinyl is removed.

- Risks exist where chipping or damaged will occur when vinyl removal is carried out with finishes including resprayed vehicles, replaced parts of vehicles, badly painted and or poor condition paint work, badly repaired or uneven surfaces.

- All paints break down and fade over time. Your Vinyl is UV which will protect your paint from fading. This may result in a colour variation between the signed and bare areas.

- Incorrect removal procedures can result in damage or stripping of the surfaces your vinyl has been applied to.

It depends on the condition of the signs which means the cost is usually higher than using new materials.

Using recycled material cost and risks include:- Cleaning, filing or hammering existing holes, rust, weather damage and degradation of surfaces.

While we commend reusing material from an environmental view the associated risks mean we do not offer a guarantee on any work using recycled materials

Photo Mugs

The current print area of our photo mug is 200mm x 90mm.

This will allow an approximate 3mm white edge around the top and bottom on the mug.

Delivery Info

Delivery outside of Australia

Our delivery services are priced and supplied for orders delivered within Australia. Shipping outside of Australia is an extra cost. For delivery outside of Australia we will contact you and advise the shipping cost to your country.

Big and Bulky orders

Some items may require special handling or are too large to deliver by parcel courier. We will quote you a shipping charge and delivery time for big and bulky items at time of order.

Larger bulky deliveries are delivered to the ground floor of the shipping address. Delivery upstairs or into spaces with tight or limited access will be quoted on a case by case basis.

Delivery time is in addition to production time. Once a job leaves by courier, it’s beyond our control. allBIZ reserve the right to substitute or change the couriers we use and recommend at all times.

STANDARD: 2 – 7 business days

Courier to metro and capital cities. Many deliveries in 1-3 days. Rural and remote destinations take longer, and may cost more.

EXPRESS : 2 - 4 business day

To capital cities and major regional centres. Rural and remote destinations take longer and may cost more. Express dispatch are at 2.00pm daily.

SAME DAY DELIVERY:

Please contact our friendly staff for details on this service.

NOTE: For security, Unattended Deliveries are at the driver’s discretion. To avoid re-delivery fees, make sure someone is available to receive the package.

CLICK and COLLECT

Order online and we will contact you when your order is ready to collect.

Available Monday to Friday and Saturday mornings 9am - 12pm. (Not available on Public Holidays.)

PRINT DELIVERY DISPATCH

Work completed before 10:00am is shipped same business day.

Work completed after 10:00am is shipped next business day.

Completed Same Day and Next Day orders will be collected by courier on the next pickup cycle (Standard or Express).

Deliveries are between between 8:00 am and 5:00 pm from Monday to Friday. Deliveries not available on weekends or public holidays.

DELIVERY OUTSIDE OF AUSTRALIA

We only deliver within Australia. Shipping outside of Australia is an extra cost. For delivery outside of Australia we will contact you and advise the shipping cost to your country

BIG AND BULKY

Some items may require special handling or are too large to deliver by parcel courier. We will quote you a shipping charge and delivery time for big and bulky items at time of order.

Larger bulky deliveries are delivered to the ground floor of the shipping address. Delivery upstairs or into spaces with tight or limited access will be quoted on a case by case basis.

The allBIZ team, along with our delivery partners, make every reasonable and professional effort to have your job delivered on time. But sometimes really big things happen that we can’t control. Things like website failure, a power outage, a natural disaster, or an attack by Godzilla*.

If something beyond our control does happen, we will make every reasonable effort to have your order to you as soon as possible. Our team are happy to provide tracking information and estimated delivery time on request.

*Godzilla attacks are very rare nowadays. Hardly worth mentioning.

Online Account and Files

- go to MY ACCOUNT / PAST ORDERS

- select the order

- click on VIEW DETAILS

- click ORDER HISTORY DETAILS tab

You can re-order jobs here, and leave or respond to comments about current jobs.

TO UPLOAD A NEW FILE

- go to MY ACCOUNT / PAST ORDERS

- select the order

- click on VIEW DETAILS

- click ORDER HISTORY DETAILS tab

- click SELECT FILE, navigate to it on your computer, and then hit SUBMIT

Or you can email a new file to upload@allbizsupplies.biz. Use your order number as the subject. NOTE: this email address is automated for files only. It is NOT read by humans. To leave comments, log in to your account:

- go to MY ACCOUNT / PAST ORDERS

- select the order

- click on VIEW DETAILS

- click ORDER HISTORY DETAILS tab and read/leave comments

For Help Guides, go to the product you ordered and click the ARTWORK TEMPLATE tab. Jobs need:

- to be in PDF format (PDF/X-1a is better)

- FONTS embedded (or converted to Curves/Paths/Outlines )

- IMAGES 600 to 300ppi (less resolution and they will print fuzzy and blocky)

- CMYK colour only (do not use RGB or Spot colour or mix them)

- FLATTEN transparencies/layers (or you will get odd stripes/blocks)

- BLEED - 3mm, and 3mm Safe Area away from edge

- TRIM MARKS and TRIM BOX (bleed jobs) - set to final cut size (or your job will be cut wrong)

(If you had a professional create artwork for you, the above basic standards should have been included. Your graphic artist can easily correct any inadvertent errors.)

IF YOU USED THE ONLINE DESIGN STUDIO

• go to MY ACCOUNT then PORTFOLIO

• select the order, click EDIT

• EDIT using the online editor Designer Studio

• CLICK “CONTINUE” (shopping cart in upper right)

• NAME the artwork the original name and add “Version2/etc.” so we know it is new

• TICK “I agree” and CLICK “CHECKOUT”

• DO NOT complete the order, just leave the order in the shopping cart and log out.

For Help Guides, go to the product you ordered and click the ARTWORK TEMPLATE tab. Jobs need:

- to be in PDF format (PDF/X-1a is better)

- FONTS embedded (or converted to Curves/Paths/Outlines )

- IMAGES 600 to 300ppi (less resolution and they will print fuzzy and blocky)

- CMYK colour only (do not use RGB or Spot colour or mix them)

- FLATTEN transparencies/layers (or you will get odd stripes/blocks)

- BLEED - 3mm, and 3mm Safe Area away from edge

- TRIM MARKS and TRIM BOX (bleed jobs) - set to final cut size (or your job will be cut wrong)

(If you had a professional create artwork for you, the above basic standards should have been included. Your graphic artist can easily correct any inadvertent errors.)

If you paid a graphic artist, demand the file be corrected. You have paid for a professional file that meets basic international standards. Jobs need:

- to be in PDF format (PDF/X-1a is better)

- FONTS embedded (or converted to Curves/Paths/Outlines )

- IMAGES 600 to 300ppi (less resolution and they will print fuzzy and blocky)

- CMYK colour only (do not use RGB or Spot colour or mix them)

- FLATTEN transparencies/layers (or you will get odd stripes/blocks)

- BLEED - 3mm, and 3mm Safe Area away from edge

- TRIM MARKS and TRIM BOX (bleed jobs) - set to final cut size (or your job will be cut wrong)

TO UPLOAD A NEW FILE

- go to MY ACCOUNT / PAST ORDERS

- select the order

- click on VIEW DETAILS

- click ORDER HISTORY DETAILS tab

- click SELECT FILE, navigate to it on your computer, and then hit SUBMIT

Attachments not showing

Here are some possible solutions if you do not see email attachments.

Mail for Windows 10:

Switch OFF "group by conversation."

There are many email services that can run under Mail for Windows 10, such as Hotmail, Outlook, Exchange, Gmail, Yahoo! Mail, iCloud, and any any account that supports POP or IMAP, so the details to turn off "group by conversation" are different.

In Hotmail:

Settings-->Message List-->Organization-->Individual Messages.

In Outlook:

To add or remove grouping in an arrangement, on the View menu, in the Arrangement section, click More.

In the arrangement gallery, UNclick Show in Groups.

Another possible solution is to make sure you are sending and receiving in HTML and not Plain Text or Rich Text.

Some other causes can be anti-virus software, weak mobile reception and/or heavy mobile traffic.

Signage safety Information

Due to recent Australian Standards changes regarding ACM (Aluminium Composite Material) for building cladding, this product is not compliant to AS 1530.1.

ACM signage was broadly included in the new standards, and is slowly being given a separate standard.

Until new standards (AS and Building Code) are finalised, it is important to check with all relevant bodies and councils for your project.